Cybermasyer Series inverter precision air conditioner is based on the ordinary air conditioner and uses a special inverter compressor and adds a variable frequency control system. The main unit of the inverter precision air conditioner is automatically variable speed. It can automatically provide the required amount of cooling (heat) according to the room conditions. When the indoor temperature reaches the desired value, the main unit of the air conditioner will operate at a constant speed that can accurately maintain this temperature. operation to achieve “non-stop operation” to ensure the stability of the ambient temperature.

.

Adopting modular design, it is suitable for integral temperature control solution in data centre, base station, battery room, equipment room and other places.

|  |  |  |

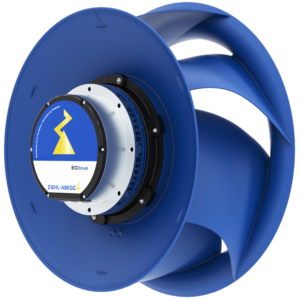

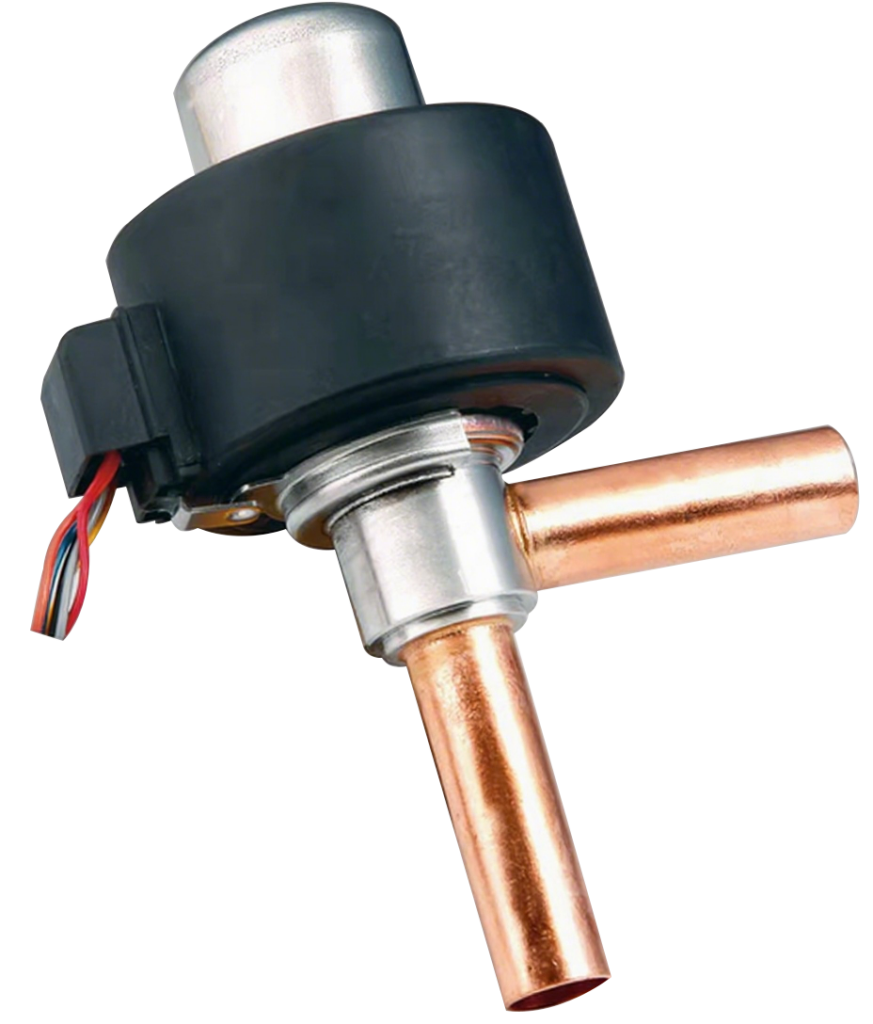

EC Fans | Compressor | Electronic Expansion Valve | Humidifier |

| The backward centrifugal EC fan with high efficiency and reliability is adopted, featuring large air volume, stable operation, long air supply distance, and wide static pressure range adjustmen. | Copeland flexible scroll compressor with high efficiency, can dynamically output cooling capacity according to demand, energy saving, and high efficiency. | Expansion valve adopts advanced thermal expansion valves with strong reliability and stability and can precisely control the supply of refrigerant. | An internationally advanced electrode steam humidification system under which the amount of humidification and water inflow and outflow are all controlled by computer. |

Coolnet has a crucial mission in the digital age. In innovating data centers, we explore new concepts and use advanced tech. The modular design meets various needs, and cooling/smart systems ensure efficiency. For connections, we optimize networks for fast data transfer. Leading the era, we help all clients, startups or established, thrive via emerging tech.

Support on emand expansion

Provide 24*7 online service

Offer reliable technical support